The analysis in environments with explosion risk is a critical process to identify and mitigate potential hazards.

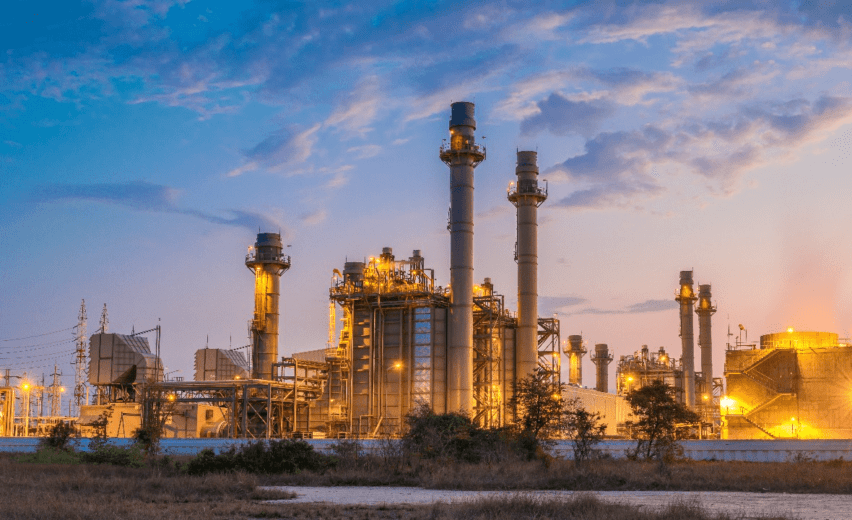

The analysis in environments with explosion risk is a critical process to identify and mitigate potential hazards. These environments include areas where flammable or combustible substances are present, such as oil refineries, chemical factories, gas facilities, and other industrial locations. The following are some guidelines that can help identify and mitigate the risks associated with these hazardous environments:

Identify the risks: The first step is to identify all potential risks in an environment with explosion risk. This may include the presence of flammable substances, toxic gases, electrical equipment, or other hazardous materials. By identifying these risks, it is possible to create a comprehensive list of potential hazards.

Assess the risks: After identifying the risks, assess the likelihood that these hazards will occur. This includes analyzing the frequency and severity of potential risks and identifying the consequences of each event.

Determine preventive measures: Based on the risk assessment, determine preventive measures to minimize or avoid hazards. This may include the installation of safety systems, such as fire extinguishers, personal protective equipment, ventilation systems, and gas detection.

Implement preventive measures: After determining preventive measures, it’s time to implement them. Make sure all safety equipment is operational, and all employees have access to personal protective equipment and adequate training.

Monitor and revise: It’s important to continuously monitor the environment to ensure preventive measures are working properly. Additionally, periodically review the risk analysis plan to ensure it’s up-to-date and effective.

In summary, risk analysis in environments with explosion risk is a complex process that requires a careful evaluation of potential risks and implementation of appropriate preventive measures. It’s important to ensure all safety equipment is operational, employees have access to personal protective equipment and adequate training, and the risk analysis plan is reviewed and updated regularly.