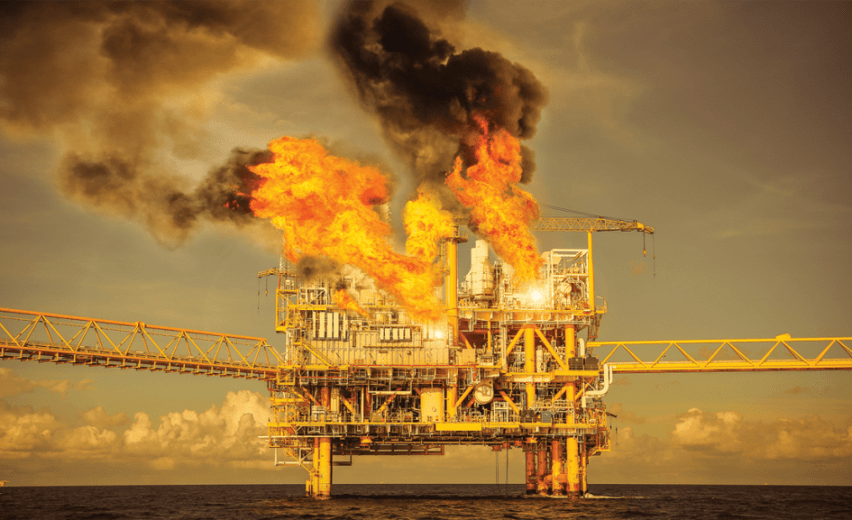

Identifying explosive atmospheres is a fundamental part of safety management in industrial or commercial environments.

You likely have come across the concept of explosive atmospheres. This term, which is becoming increasingly common in the industry at large, relates to the combination of flammable elements such as gases, vapors, mists, dusts, or fibers with the air.

Today, we will address the importance of monitoring explosive atmospheres for your company’s safety.

Monitoring Explosive Atmospheres

Identifying explosive atmospheres is a fundamental part of safety management in industrial or commercial environments, especially where flammable substances are present. Explosive atmospheres occur when a mixture of flammable substances (gases, vapors, mists, or dusts) combines with air and creates an environment where ignition can occur, resulting in an explosion. Here are some steps to identify explosive atmospheres in your company:

Identification of Flammable Substances: Identify all flammable substances present in your company, including gases, flammable liquids, vapors, combustible dusts, etc. Consult the safety data sheets (SDS) of the chemicals used to obtain information about their flammability.

Risk Assessment: Conduct a detailed risk assessment in all locations where flammable substances are present. Consider factors such as the quantity of substance, frequency and duration of exposure, ventilation conditions, and the presence of ignition sources.

Area Classification: Classify the areas in your company according to explosion risk zone or class criteria. This helps determine the likelihood of an explosive atmosphere being present. Classifications are usually divided into Zones (0, 1, 2 for gases; 20, 21, 22 for dusts) or Classes (Division 1, Division 2 in the US).

Monitoring and Measurement: Implement monitoring systems to detect the presence of flammable gases, vapors, or dusts in real time. This may include gas detectors, concentration meters, and other monitoring devices.

Ignition Source Control: Identify and control potential ignition sources such as open flames, electrical sparks, electrical equipment not suitable for hazardous areas, static electricity, among others.

Adequate Ventilation: Ensure proper ventilation in areas where flammable substances are handled or stored. This helps dilute and disperse any explosive atmosphere.

Safe Operating Procedures: Develop safe operating procedures that address the handling, storage, and transportation of flammable substances, as well as measures to prevent the formation of explosive atmospheres.

Training and Awareness: Train employees about the risks associated with explosive atmospheres, prevention measures, and how to respond in emergencies.

Regular Maintenance: Conduct regular maintenance on equipment and monitoring systems to ensure they function properly and are calibrated.

Audits and Inspections: Carry out regular audits and inspections to ensure ongoing compliance with safety measures and identify any deficiencies that may arise.

Keep in mind that identifying and preventing explosive atmospheres requires a comprehensive approach, involving various aspects of industrial safety. It is advisable to consult safety experts and adhere to local, national, and international regulations related to explosion prevention and fire protection.

How can Comquality Engenharia assist your company?

“Comquality Engenharia is the first company in the North-Northeast region and the third in Brazil to be certified in the technical competence of ABNT NBR IEC 60079-17, demonstrating our ability to perform inspection and maintenance of equipment and electrical installations in classified areas.”

We have a specialized team dedicated to providing optimized solutions in Explosive Atmospheres and Area Classification. Additionally, our professionals hold personal certifications recommended by IECEx, ensuring the quality of our service delivery.

Do you need assistance with the inspection and maintenance of explosive atmospheres in your company’s installations? Get in touch!

📞 71 3622-1255

📩 comercial@comquality.com.br

🌍 www.comquality.com.br