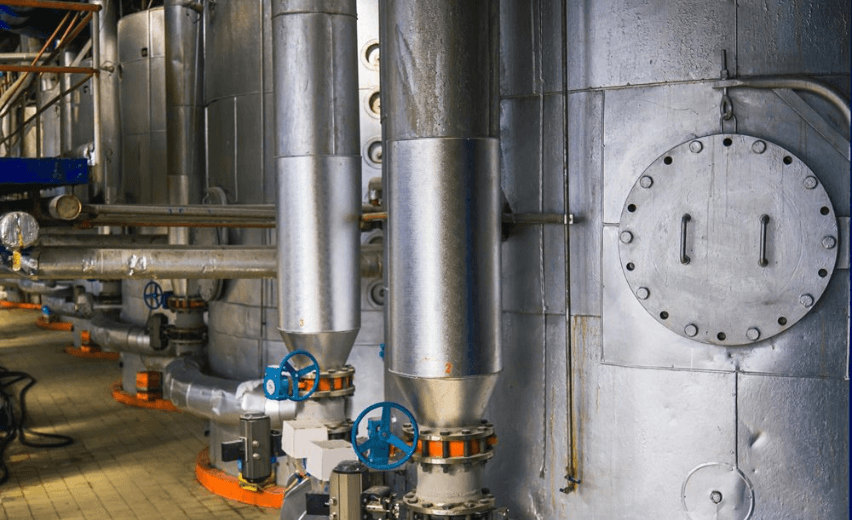

Mechanical equipment in explosive atmospheres presents significant risks due to the possibility of igniting flammable substances.

Mechanical equipment in explosive atmospheres presents significant risks due to the possibility of igniting flammable substances present in the environment.

Examples of non-electrical equipment include:

- Couplings

- Pumps

- Gearboxes

- Hydraulic and pneumatic motors

There are generally two situations in which ignition generated by mechanical equipment needs to be considered:

- Mechanical equipment failure, such as bearing overheating.

- Ignition caused by abnormal operation of mechanical equipment, such as hot braking surfaces.

To prevent these risks, it is crucial to understand the hazards involved and implement appropriate safety measures. Below, we describe the main risks and how to prevent them:

Risks of Mechanical Equipment in Explosive Atmospheres:

- Sparks and Heat: Mechanical equipment can generate sparks or heat during its operation, which can serve as a source of ignition in explosive atmospheres.

- Friction and Wear: Friction between moving parts of mechanical equipment can generate enough heat to cause ignition in an explosive atmosphere.

- Electrical Discharges: Electrical equipment, such as motors and switches, can generate electrical discharges that can ignite flammable substances.

Prevention of Risks of Mechanical Equipment in Explosive Atmospheres:

- Area Classification:

- Identifying and classifying areas where explosive atmospheres may be present is the critical first step. This helps determine what prevention measures are necessary in each zone.

- Selection of Suitable Equipment:

- Choosing certified mechanical equipment for use in explosive atmospheres is essential. Such equipment is designed to reduce the risk of ignition.

- Intrinsic Safety:

- Use electrical and mechanical equipment designed with intrinsic safety, which reduces the available energy for sparks or heat to safe levels.

- Regular Maintenance:

- Perform regular preventive maintenance to ensure that equipment is in good working condition. This includes inspections, lubrication, and replacement of worn parts.

- Grounding and Shielding:

- Ensure that equipment is properly grounded to prevent the accumulation of static charges that could cause sparks. In some cases, shielding may be necessary to prevent the ingress of dust or flammable gases.

- Certifications and Compliance:

- Verify that mechanical equipment meets local and international standards and regulations, including certifications for use in classified areas.

- Operator Training:

- Provide adequate training to operators so they understand the risks and know how to operate the equipment safely.

- Monitoring and Detection:

- Implement continuous monitoring systems and gas detection to alert to the presence of flammable substances in the environment.

- Change Management:

- Carefully evaluate any modifications to processes or facilities that could affect the explosive atmosphere and take appropriate measures.

In conclusion, there is still a misconception regarding the risks of equipment and installations in explosive atmospheres. Much of the focus is on electrical installations, while the potential dangers posed by non-certified mechanical equipment, not managed correctly, are often underestimated. Therefore, the prevention of risks in explosive atmospheres is essential to ensure the safety of workers and the integrity of facilities. Strict compliance with specific standards and regulations for classified areas is crucial, and employee awareness and training play a vital role in accident prevention.

A proactive approach to the safe maintenance and operation of mechanical equipment is essential to prevent incidents in potentially hazardous environments.

How Comquality Can Help Your Company:

Comquality Engenharia is the first company in the North-Northeast and the third in Brazil to be certified in the technical competence ABNT NBR IEC 60079-17, demonstrating our ability to perform inspection and maintenance of electrical equipment and installations in classified areas.

We have a specialized team dedicated to delivering optimized solutions in Explosive Atmospheres and Area Classification, and our professionals hold the certifications recommended by IECEx, ensuring the quality of our services.

For more information about our services or to discuss your specific needs, please do not hesitate to contact us. We look forward to working together and facing future challenges collaboratively and successfully.

📞 71 3622-1255

📩 comercial@comquality.com.br

🌍 www.comquality.com.br